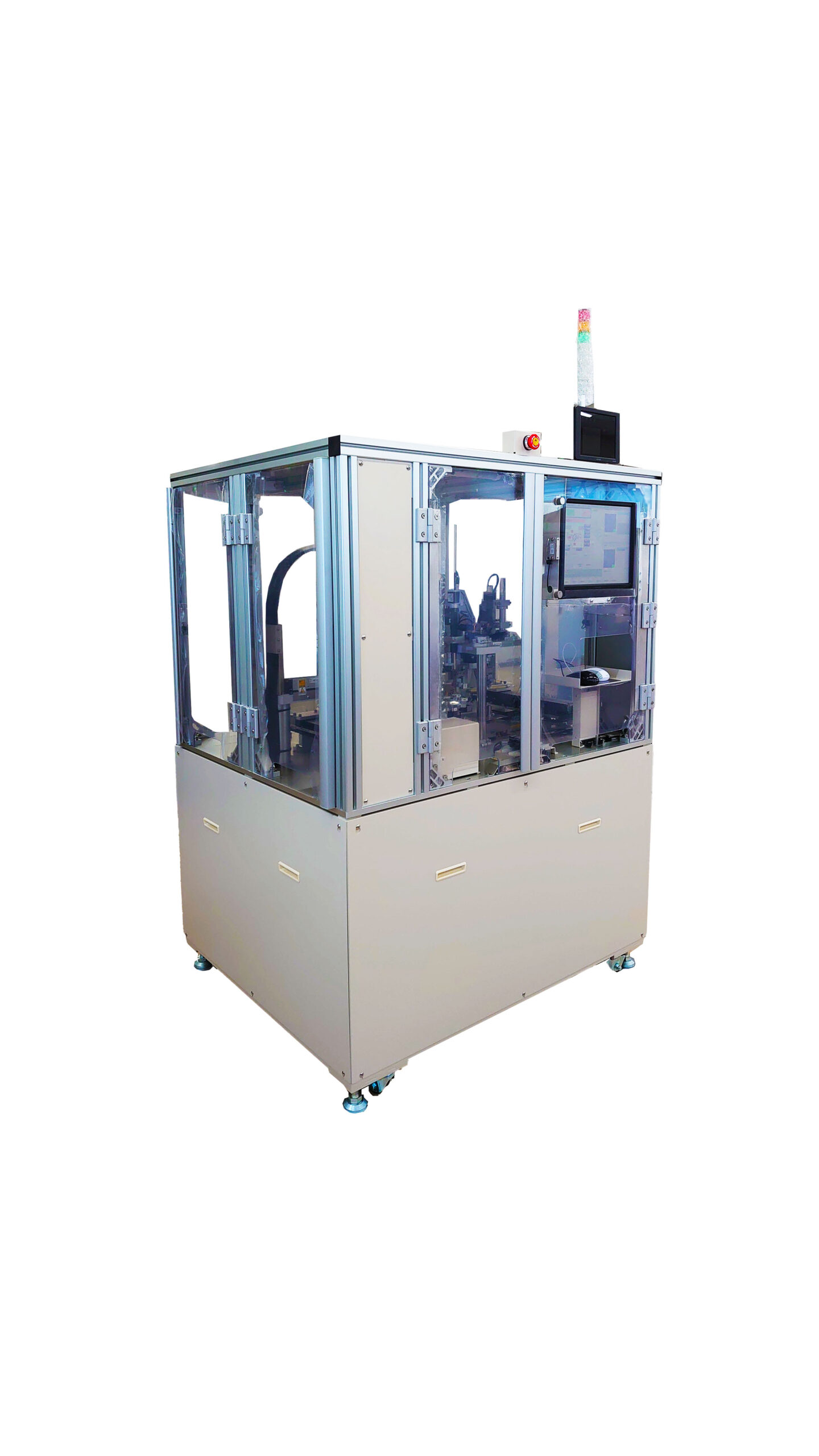

The quartz wafer's chips are folded and placed inside the empty tray. Following image processing to adjust the chips' position, the wafer's chips are folded and then reinserted into the appropriate jig. It is possible to read the wafer ID and fold out the mapping data (frequency rank minutes, bad marks).

| Target Product | Quartz crystal wafer chips 2 - 4 in. |

| Capacity | 4000p/h (0.9sec/p) |

| Wafer Storage | Blank tray |

| Wafer ID Reading | Image recognition device or barcode input |

| Chip Correction | Position correction by image recognition devices |

| Transfer Method | Vacuum suction transfer (nozzle and index) |

| External Dimensions | 1200(W) x 1000(D) x 1650(H) |